How to Dry and Cure Homemade Cheese

Drying and curing cheese is a key step in making cheese. It needs a steady temperature and humidity to make great cheese. The best temperature for aging cheese is between 52-55°F1.

To get this right, you need to know the basics of cheese drying and curing. This includes controlling temperature and humidity. You can do this at home using homemade methods to dry and cure cheese. The fat in dairy products, like whole milk with 8 grams of fat per cup, is also important2.

When drying cheese at home, think about the milk type. Cow’s milk has 88% water, 3.25% fat, and 3.25% protein. It also has 4.8% sugar, and 0.7% minerals and vitamins2.

Keeping everything clean is key. Wash all equipment with detergent and water before and after use. Use a bleach-water solution for sanitizing, with 1 tablespoon of bleach per 1 gallon of water2.

Key Takeaways

- Consistent temperature and humidity level are key for quality cheese

- Ideal aging temperature for cheese is between 52-55°F1

- Proper sanitation is vital to stop harmful bacteria growth2

- Fat content in dairy affects cheese quality2

- Homemade methods can be used to dry and cure cheese at home

Understanding the Basics of Cheese Drying and Curing

When you start drying cheese at home, knowing the cheese curing process is key. This process includes steps to preserve the cheese and enhance its taste and texture. The first step is cooling milk to 3-4 degrees Celsius, as mentioned in3.

The cheese curing process also uses heat to kill harmful microbes. Pasteurization heats milk to 70-80 degrees Celsius for 15-40 seconds, as3 explains. Also4, points out that cow’s milk is the most common for making cheese.

Here are some important things to think about when drying cheese at home:

- Temperature control: The drying temperature affects the cheese’s taste and texture3.

- Humidity: The drying environment’s humidity also plays a role3.

- Time: The drying time varies based on the cheese type4.

By grasping these points and following the cheese curing process, you can make tasty cheeses at home. Use a food dehydrator, oven, or microwave. The goal is to control temperature and humidity for the right dryness and flavor4.

Essential Equipment for Drying and Curing Cheese

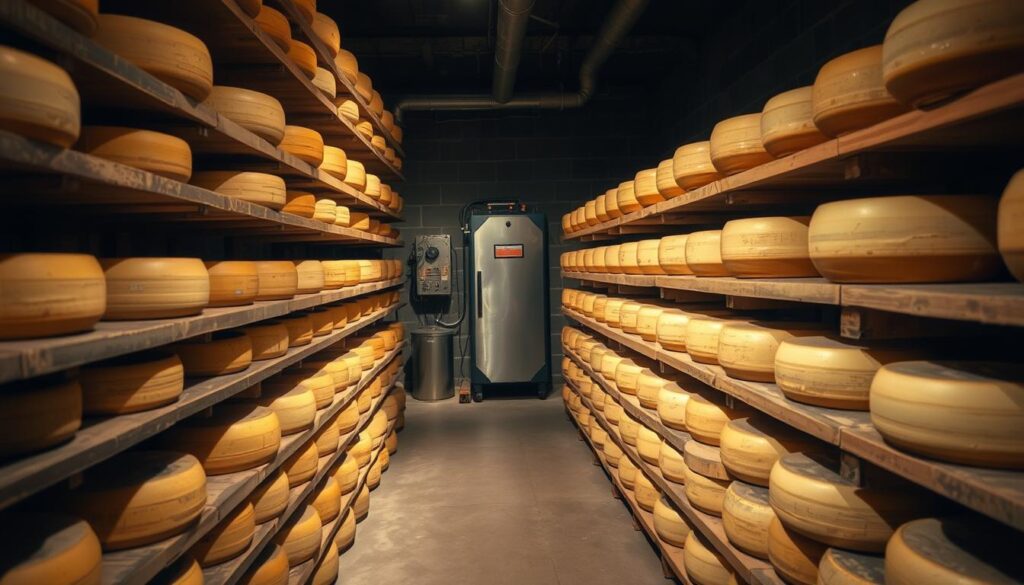

Having the right equipment is key for cheese curing. You’ll need a cheese cave or a regular fridge to age cheese. These should keep a steady temperature and humidity5. For those making cheese at home, a DIY cheese cave can be set up in a fridge or a cool, dark spot.

It’s important to control the environment for cheese curing. You must watch the temperature and humidity levels closely. The ideal aging temperature is between 45°F to 58°F6. Also, the moisture level should be about 80% to 98%6.

For precise temperature control, a dairy thermometer is essential. It should read exactly 212°F when calibrated right7. Cheese molds with holes or perforations help with whey drainage. Cheesecloth or butter muslin are used for draining and wrapping the cheese7.

For more on homemade cheese preservation, check out a DIY cheese-making guide. It offers tips and advice for beginners. With the right equipment and following these guidelines, you can cure and preserve cheese at home.

- Cheese cave or refrigerator

- Dairy thermometer

- Cheese molds

- Cheesecloth or butter muslin

These tools help control the environment. They ensure the cheese is cured and preserved well. This results in a delicious and high-quality cheese5.

The key to successful cheese curing is to maintain a consistent environment and monitor the temperature and humidity levels closely. By doing so, individuals can produce a wide range of delicious cheeses at home.

| Equipment | Description |

|---|---|

| Cheese Cave | A controlled environment for aging cheese |

| Refrigerator | A alternative to a cheese cave for aging cheese |

| Dairy Thermometer | A tool for precise temperature control |

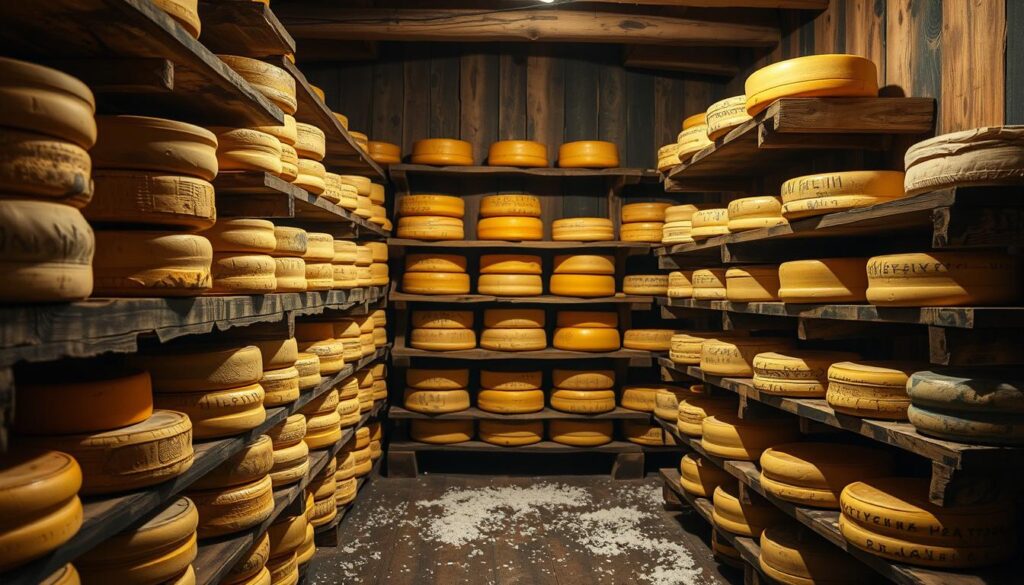

Creating the Perfect Environment for Cheese Aging

To age cheese at home, you need the right environment. This means controlling temperature, humidity, and air flow. The best aging temperature is between 52-55°F8. You should keep humidity at about 70%8 or 80-98%9.

Use a thermometer and hygrometer to keep these levels steady. Air flow is key to stop mold. Make sure there’s enough space between shelves and use a fan or humidifier if needed9.

For the best aging spot, consider a crisper drawer or a cheese cave. It should be colder than your fridge8.

Some important tips for the perfect aging spot include:

* Keep temperature and humidity steady

* Ensure good air flow

* Have enough space for cheese

* Check the cheese often to avoid mold

You can achieve the ideal aging spot with the right tools and following these tips89.

| Factor | Ideal Level |

|---|---|

| Temperature | 52-55°F8 or 45-58°F9 |

| Humidity | 70%8 or 80-98%9 |

| Air Circulation | Ample space between shelves and use of fan or humidifier if necessary9 |

By following these guidelines and using the right tools, you can create the perfect spot for aging cheese. This will help you successfully dry cheese at home.

Homemade Methods to Dry and Cure Cheese

There are many ways to dry and cure cheese at home. The process depends on temperature, humidity, and the cheese type. For instance, air-drying cheese at a low temperature (below 140°F) for hours is a traditional method10. This keeps the cheese’s natural flavors and textures.

Other methods include cave aging and modern home solutions. These options offer better control over temperature and humidity. A homemade cheddar cheese wheel can weigh about 4 pounds, leading to a total of 20 pounds for five wheels11.

Important things to consider for homemade cheese drying and curing include:

- Temperature control: The ideal temperature for drying and curing cheese can vary depending on the type of cheese being made, but it is typically between 50-55°F10.

- Humidity management: Maintaining a consistent level of humidity is critical to prevent unwanted bacteria and mold growth10.

- Air circulation: Good air circulation helps prevent moisture buildup and ensures even drying and curing10.

By using these homemade methods, people can make a variety of tasty cheeses at home. Whether using traditional air-drying or modern solutions, the key is a controlled environment. This allows the cheese to develop its natural flavors and textures.

| Method | Description |

|---|---|

| Traditional Air-Drying | Drying cheese at a low temperature (below 140°F) for several hours10 |

| Cave Aging | Aging cheese in a controlled environment with precise temperature and humidity control |

| Modern Home Aging | Using modern equipment and techniques to age cheese at home |

Different Drying Times for Various Cheese Types

When you dry cheese at home, knowing the drying times for different cheeses is key. Hard cheeses like cheddar and parmesan need more time than soft cheeses like mozzarella and feta12. This is because hard cheeses have less moisture, making them better for drying and keeping13.

A general guideline for drying times is as follows:

| Cheese Type | Drying Time |

|---|---|

| Hard Cheeses (e.g., cheddar, parmesan) | Longer drying time (several weeks or months) |

| Soft Cheeses (e.g., mozzarella, feta) | Shorter drying time (several days or weeks) |

| Blue Cheeses | Varying drying times depending on the specific type |

The drying time can also change based on temperature, humidity, and the homemade cheese preservation methods used14. By understanding these factors and adjusting the drying time, you can get the perfect flavor and texture in your dried cheese.

Remember, the secret to successful drying cheese at home is patience and paying close attention. With the right techniques and tools, you can make many tasty and lasting cheeses using homemade cheese preservation methods13.

The Role of Salt and Moisture in Cheese Curing

The cheese curing process needs a balance of salt and moisture to make great cheese. Salt stops harmful microbes from growing, helping the cheese stay fresh15. It also helps the cheese lose moisture, changing its texture and keeping it stable15. Knowing how salt and moisture work is key for making cheese at home.

There are ways to add salt to cheese, like dry salting and brine salting. Dry salting is used for cheeses like Cheddar and Colby. It helps the cheese absorb salt and lose moisture better15. Brine salting, on the other hand, soaks the cheese in salty water. This method is good for cheeses like Mozzarella and Feta, letting salt soak in slowly15. To learn more, check out cheese curing techniques.

It’s important to watch the cheese’s moisture level to get the salt right. The moisture needed changes based on the cheese type. For example, extra-hard cheeses need 25-35% moisture, while hard cheeses need 35-45%16. Keeping the moisture right helps avoid cracks and makes the curing process smoother.

By managing salt and moisture, cheese makers can make many different cheeses. With over 2,000 cheese types worldwide, there’s always room for new ideas16. Whether you’re experienced or new, understanding salt and moisture is key to making tasty cheese.

Common Problems and Troubleshooting

When you dry cheese at home, you might face some issues. Mold growth is a common problem. It can be stopped by keeping things clean and controlling humidity17. Another issue is drying the cheese too much, making it hard and crumbly17.

To fix these problems, knowing the causes is key. For example, not using enough or active rennet can cause curds to fall apart17. Too much rennet or overworking can make the cheese rubbery18. So, it’s important to follow the right steps for drying cheese at home.

Here are some common problems and how to solve them:

- Mold growth: maintain a clean environment and control humidity level17

- Over-drying: monitor temperature and humidity levels17

- Rubbery cheese: avoid excessive rennet use or overworking18

Knowing these common problems and how to avoid them can help you succeed in drying cheese at home. For more cheese making tips, check out cheesevibes.com. They have lots of info on different cheeses and their characteristics17.

Safe Storage During the Curing Process

When making Homemade Methods to Dry and Cure Cheese, keeping it safe is key. The cheese curing process needs the right storage. This includes the right temperature and humidity levels. Most cheeses need a humidity of 75% to 95% during curing19.

Choosing the right container is vital for storing cheese. Consider these factors:

- Temperature control: Keep the temperature between 10-13°C for curing19.

- Humidity management: Aim for 65-75% humidity to avoid cracking, more so in winter20.

- Air circulation: Good air flow helps stop mold and bacteria growth.

By following these tips and using the right container, you can store cheese safely. This ensures your homemade cheese is of high quality. Safe storage also helps avoid cross-contamination and foodborne illness21.

Signs of Properly Cured Cheese

When you’re drying cheese at home, knowing when it’s done is key. A good cheese should feel dry and smooth to the touch. It should also be firm and crumbly22. The cheese’s color can tell you about its curing level. A yellow cheese often means it’s been cured with foods high in beta-carotene22.

To cure cheese right, you need to control the temperature and humidity. The best aging temperature is between 52-55°F. The humidity should be 65-75%22. Keeping an eye on these levels is important. In cold weather, you might need to add water to the air to keep humidity up22.

A cured cheese should smell great. The smell can change based on the milk and how long it’s aged. But, too much moisture can cause mold. To avoid mold, make sure to dry the cheese well before wrapping it22.

For more tips on curing cheese at home, check out cheesemaking.com. By following these steps and using the right methods, you can make delicious cheese at home.

| Characteristics | Properly Cured Cheese |

|---|---|

| Surface | Dry, smooth |

| Texture | Firm, crumbly |

| Color | Yellow-hued (depending on milk diet) |

| Aroma | Developed, influenced by milk and aging process |

Advanced Techniques for Specialty Cheeses

Creating specialty cheeses like washed-rind and blue cheeses needs special techniques. For example, washed-rind cheeses get their red or orange color from certain bacteria23. Cheese makers must control the environment closely, keeping humidity between 65-75% for the best homemade cheese preservation methods24.

The aging temperature is also critical, ranging from 45-60°F for the best results24. Regular oil rubbing helps control moisture and prevent mold, mainly in the first month24. Blue cheeses, on the other hand, are aged at 8-10°C (46-50°F) with 90-95% humidity23.

To excel in making specialty cheeses, it’s vital to grasp the various methods and techniques of the cheese curing process and homemade cheese preservation methods. By managing the environment, watching temperature and humidity, and adding specific bacteria or mold, cheese makers can craft unique and tasty specialty cheeses23.

Conclusion: Mastering the Art of Cheese Curing

Mastering cheese curing takes patience, precision, and a deep understanding of the science25. Cheese has been around for about 8,000 years. The drying and curing process has changed over time, giving us many flavors and textures26.

Whether you try traditional air-drying or modern home aging, success comes from the right temperature, humidity, and air27. The formation of crystals in cheese depends on these factors. Knowing how they work is key to making great homemade cheese27.

Keep improving your skills and trying new things. Always watch your cheese as it cures. Check its look, feel, and smell to make sure it’s perfect25. With hard work and a love for trying new things, you’ll soon be making delicious homemade cheeses26.

FAQ

What happens during the cheese drying process?

Cheese drying removes excess moisture. This makes the cheese have the right texture and consistency. It also prepares it for curing.

What is the science behind cheese curing?

Cheese curing involves beneficial bacteria and mold growth. They help develop the cheese’s flavor, aroma, and texture. Temperature and humidity levels are key.

Why is proper drying and curing important for cheese?

Proper drying and curing make high-quality cheese. They help develop the cheese’s unique flavor, texture, and appearance. They also ensure food safety and extend shelf life.

What essential equipment is needed for drying and curing cheese?

You need a cheese cave, a regular fridge, or a DIY setup. Temperature and humidity control are vital for the right environment.

How can I create the perfect environment for cheese aging?

Aim for a temperature of 52-55°F and 80-90% humidity. Use a thermometer and hygrometer to check these. An air circulation system helps maintain the environment.

What are some homemade methods to dry and cure cheese?

You can use air-drying, cave aging, or modern home aging. These methods control temperature, humidity, and air circulation for the best results.

How do drying times vary for different cheese types?

Drying times differ by cheese type. Hard cheeses like cheddar need longer times, while soft cheeses like mozzarella need less. Temperature and humidity also affect drying time.

What is the role of salt and moisture in cheese curing?

Salt controls harmful bacteria growth and affects flavor and texture. It can be applied through dry or brine salting. Monitoring moisture is key for the right salt balance.

What are some common problems and troubleshooting tips for cheese drying and curing?

Problems include mold, cracking, and over-drying. Keep the environment clean, control humidity, and address issues quickly to solve these problems.

How can I safely store cheese during the curing process?

Use a cheese cave, fridge, or DIY storage. Ensure consistent temperature and prevent cross-contamination for safe storage.

What are the signs of properly cured cheese?

Look for a dry, smooth surface and firm texture. A distinct aroma is also a sign of proper curing. Check visual indicators, texture, and aroma to confirm.

What are some advanced techniques for creating specialty cheeses?

Techniques for specialty cheeses include making washed-rind and blue cheeses. These require specific bacteria and aging processes for unique flavors and textures.